Technology

Saving energy with lubricants?

With rising energy prices and growing awareness of environmental impact, it is becoming increasingly important to use and save energy efficiently. One way to achieve energy savings is to use high-performance lubricating greases, which can reduce friction in machinery and equipment.

Reading time: ca. 3 min. | An article by Julian Wald | TUNAP Blog

Key role in saving energy

Saving energy is an important issue in today's world. With rising energy prices and growing awareness of environmental impact, it is becoming increasingly important to use and save energy efficiently. One way to achieve energy savings is to use high-performance lubricating greases that can reduce friction in machinery and equipment. TUNAP wants to make a contribution here and has developed and launched the high-performance lubricating grease TUNGREASE LMO-2/40.

TUNGREASE LMO-2/40 is characterized by the use of high-quality, low-viscosity base oils. Compared to standard EP greases, it is thus possible to achieve particularly low movement resistance and thus high smooth running in applications such as ball bearings, gears or linear guides. This concept is already used in low-friction engine oils, which significantly reduces fuel consumption.

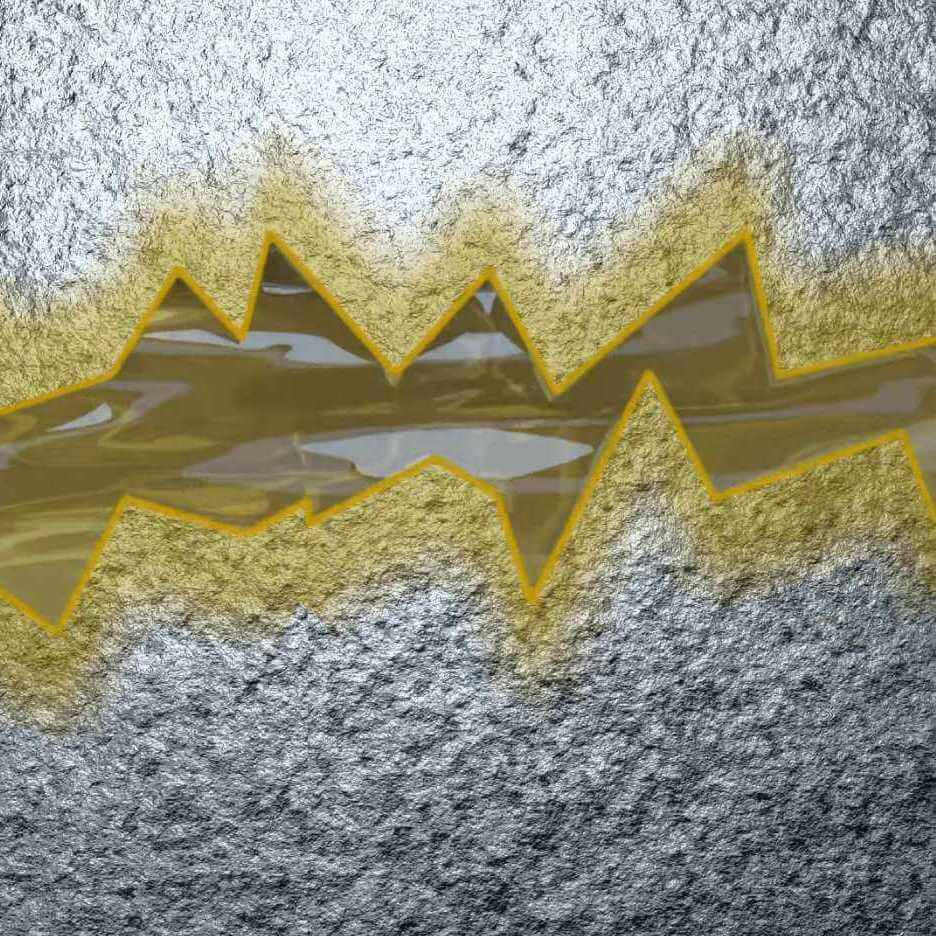

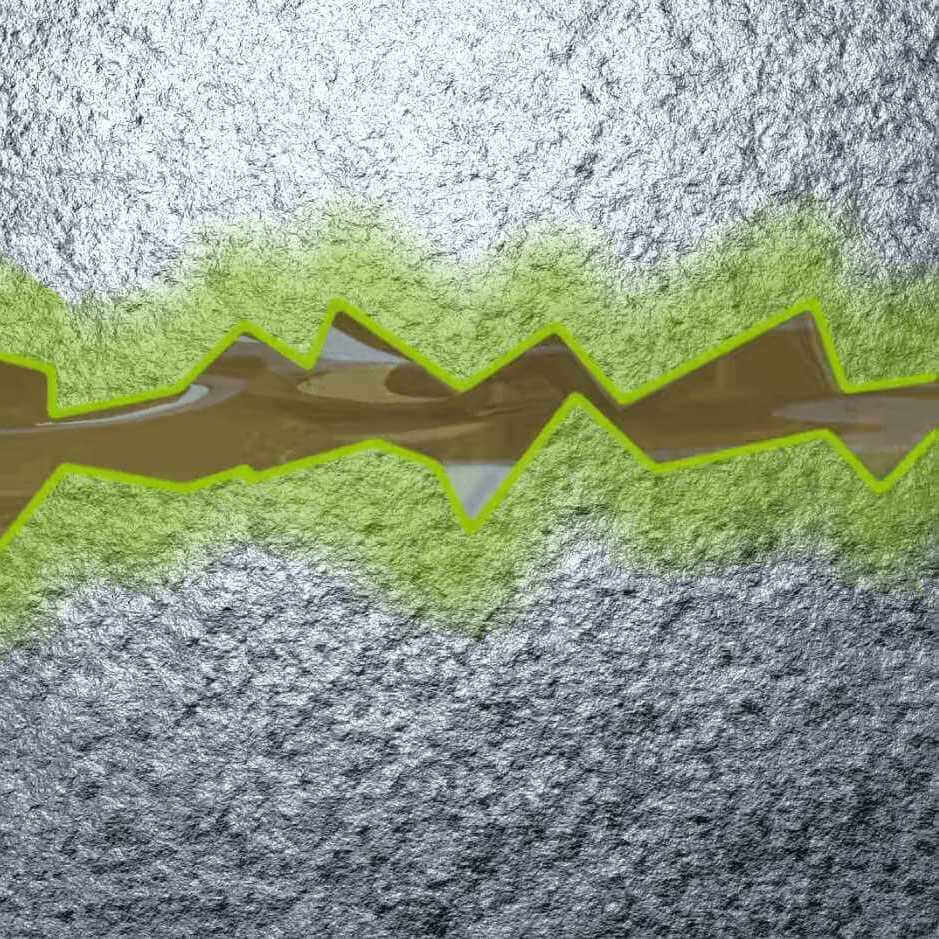

What is the difficulty? After all, simply using low-viscosity base oils is not witchcraft. The challenge is to protect the metal surfaces that rub against each other against wear. TUNGREASE LMO-2/40 is equipped with state-of-the-art additives, also known as OMC₂ technology.

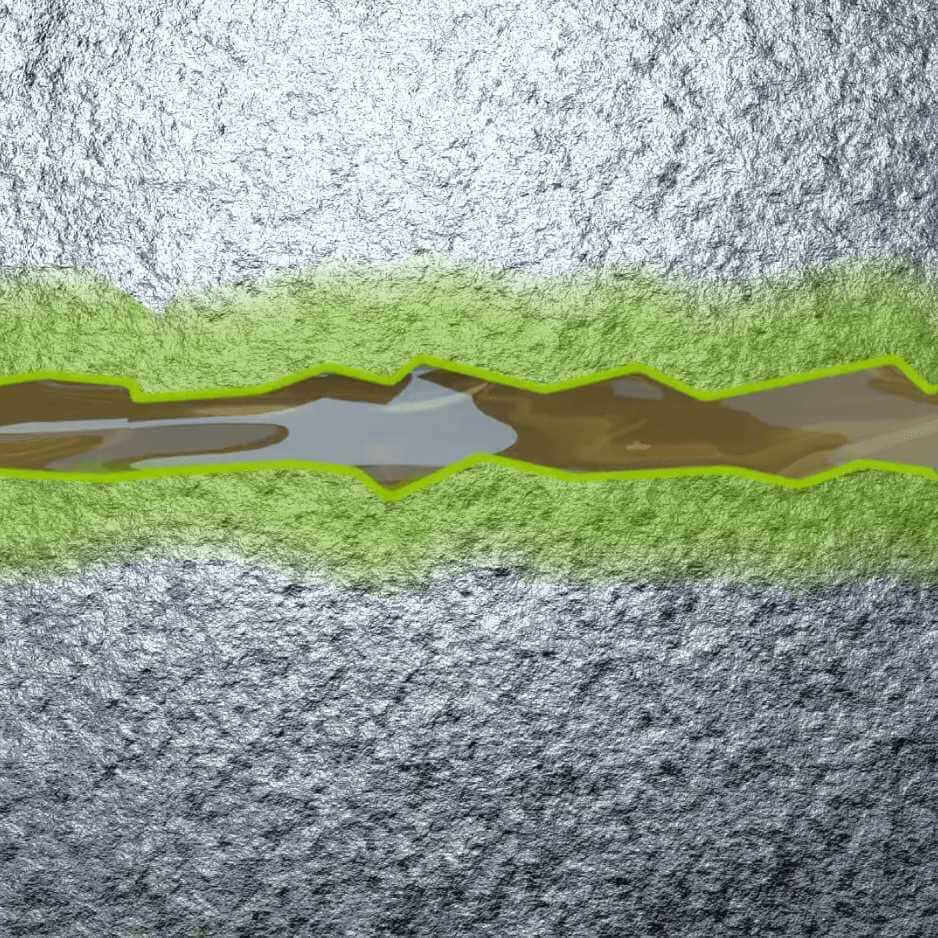

By smoothing the surface, unevenness in the surface structure is reduced and at the same time the proportion of the load-bearing surface is increased. This therefore not only effectively reduces friction, but also reliably protects against wear. In many cases, this can even be directly measured in terms of lower heat generation. An additional advantage is the longer lubricant service life or extended relubrication intervals, as the temperature load is reduced and thus lubricant aging is slowed down.

Three-phase effect of the OMC₂ technology

Overall, TUNGREASE LMO-2/40 offers potential savings in the energy consumption of plant and machinery due to its low base oil viscosity and high-performance OMC2 technology. By using TUNGREASE LMO-2/40, companies can therefore not only reduce costs, but also make an important contribution to sustainability and environmental friendliness.